LH103

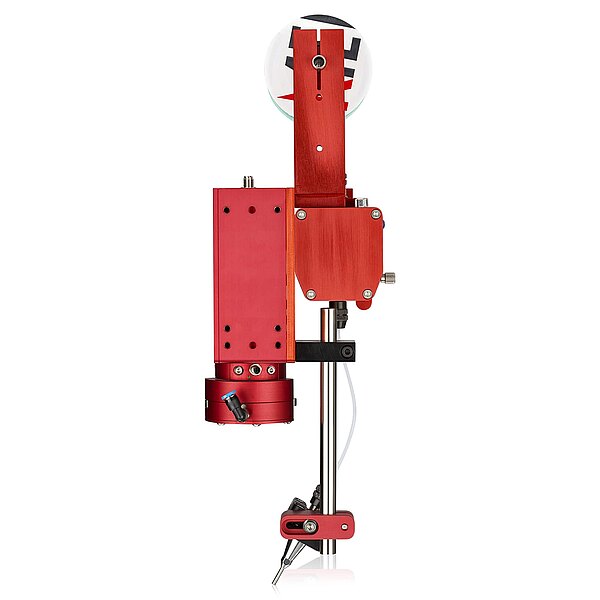

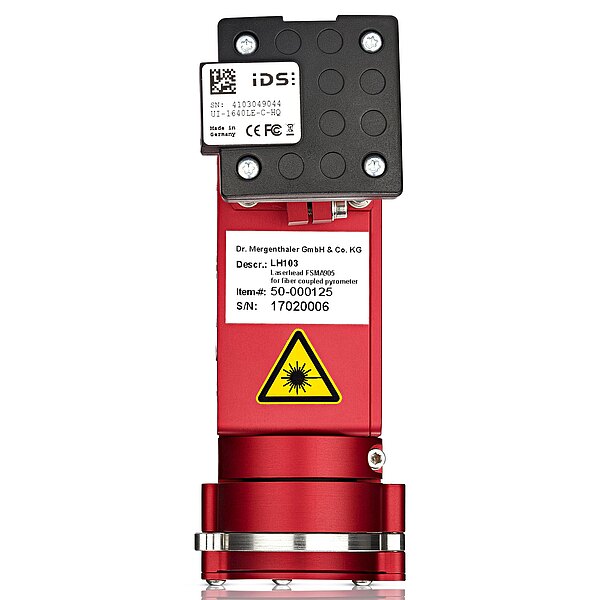

Mini Laser processing head with coaxial pyrometer and CCD cameraLH103 is a miniature laser processing head with coaxial, fiber coupled infrared pyrometer and camera

- For fiber coupled diode lasers up to 100W cw

- Diode laser wavelength 808nm to 980nm, fiber N.A.0,22

- Connector FSM905

- 1" optics

- Optional with one or two solder wire feeders for laser soldering

The compact laser head LH103 is perfectly suited for integration in machines and plants.

Especially for applications with limited space we offer the extremely compact laser head LH103 with a pyrometer and a CCD camera, which are reflected in the beam path of the laser. With a weight of about 1.5 kg, this laser processing head can be mounted on light machine axes. The LH103 can be used up to a maximum of 100W laser power.

The CCD camera is used for process monitoring and is connected to the LASCON Camera Manager.

Alternatively, an image processing camera can also be integrated.

This allows positioning of the machining head via an image processing system.

The lenses of the laser head can be exchanged so that, for example, it is easy to switch from point optics to line optics.

Especially for laser soldering, a precision wire feed has been developed. It has a response time of 1ms and a resolution of 0.01mm. An integrated encoder is used to detect the end of the wire and detects any errors during the feeding process. The function of solder wire feeding is fully integrated into the LASCON scripting language. Therefore there is no extra wiring.

The pyrometer measures temperature typically above approx. 120° C. Optionally from approx. 70° C.

The properties of the infrared pyrometer integrated in the laser head correspond to the pyrometers on our pyrometer page.

Please note: Our digital pyrometers are part of the measuring and control system LASCON ®.

- Suitable for optical power up to 200 W

- Wavelengths 808nm to 980nm

- AR coated, replaceable optics

- Coaxial infrared pyrometer and CCD camera

- Optional image processing system for improved positioning

- Optional image processing system for wire start detection

- Typical measuring range of the infrared pyrometer 140°C - 700°C, other measuring ranges up to 2500°C on request

- Fiber Optic Connectors FSMA905, N.A. 0.22

- Minimum laser spot from approx. 100μm

- Visible pilot light, brightness adjustable via LASCON Process Manager software

- Low weight (about 1.5kg, incl. wirefeeder)

Due to the compact dimensions this laser procesing head is very well suited for integration in machines and plant with little space and also for table robots

This also includes machining with several laser systems simultaneously on one component.

Applications include laser soldering, laser plastic welding and laser heating during thermal bonding or soldering on wafers.

The laser head LH103 can also be easily combined with our wire feeder SWF100, so that an extremely compact laser soldering head is created, which, due to its low weight, can be easily adapted to desktop robots.

The coaxial CCD camera is connected to the LASCON Camera Manager.

The CCD camera can optionally be replaced by an image processing camera. The image processing allows an exact positioning above the solder pad. The image processing system also allows the exact detection of the wire beginning before the soldering process.